Transparency is Our Strength

Third Party Textile Inspection Company Providing Customized Quality Management Solutions in Pakistan

A team of textile technologists offering quality control and quality assurance services to …Learn More

Who we are

Textile engineers and quality management specialists with more than 2 decades of industry experience

What we do

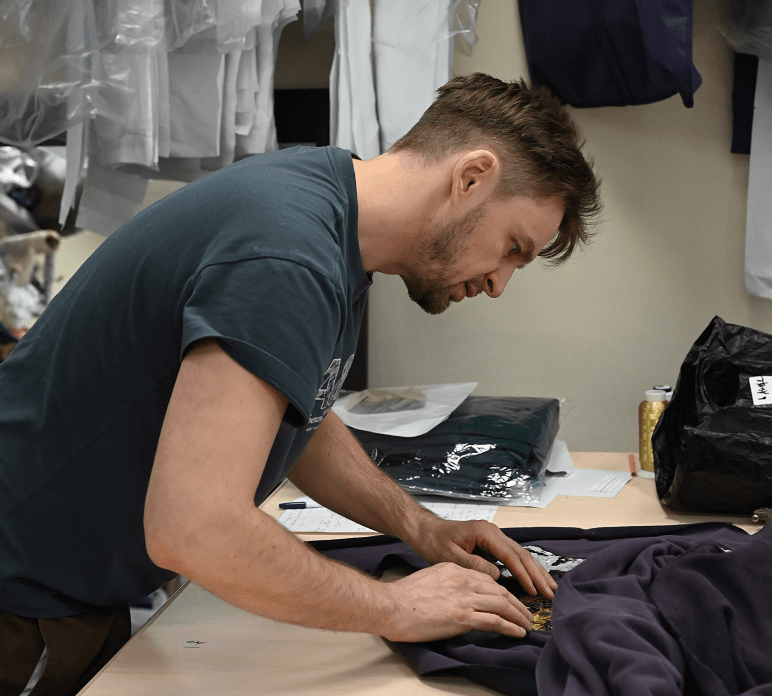

3rd party quality inspection services for all type of textile finished goods and raw materials

Why Choose Us

We love what we do. We do it with integrity. You hire us for quality inspection services. We deliver with transparency.

ABOUT TEXTILIANS

All Your Quality Inspection Needs

We are a team of textile engineers and quality management specialists with more than 2 decades of industry experience. Our product knowledge and operations understanding help us to create a difference in our customer’s experience while using our quality inspection services.

Our Vision

- Achieving maximum possible quality level

- No Re-Inspection at client’s destination

- End user satisfaction in terms of product quality

- Avoid problems instead of solving problems

Our Mission

- Customized Quality Management Solutions

- Focusing Textile Industry only

- Preferred Customer Experience

- Your eyes, ears & hands at factory floor

Our Industry Experience

No Of Inspections

Factories

Customers

OUR SERVICE

Third Party Textile Inspections

These are our most wanted inspection services. You can also set up a call with us to discuss more flexible and customized inspection solutions according to your needs.

In-Line / DUPRO During Production Inspection

⦁ Conducted when 20-50% production is completed

⦁ Workmanship, aesthetic, size measurement, raw material specs and accessories are checked

Final / PSI

Pre-Shipment Inspection

⦁ Conducted when 50-80% production is completed and goods are ready to ship

⦁ Quantity is verified

⦁ Products are randomly selected for inspection

Total Quality Management Solution

⦁ We start working right after the purchase order is committed between the customer and supplier

⦁ Keep following up with factory for induction of raw materials

Factory Evaluation

⦁ We visit the factory on behalf of our customer and cross check its details

⦁ Factory’s physical presence and operations are cross checked against its business profile

Random Sample Pick

⦁ We pick up a sample randomly from the ready shipment

⦁ Customer will receive the best and true representation of their shipment at factory

Production Monitoring

⦁ We visit factory and update our customer about production of a specific purchase order

⦁ Factory’s in-house data related to production process is checked and reported

Container Loading Inspection

⦁ Conducted while container is going to be loaded with goods ready to Ship.

⦁ We make sure that products are packed correctly and will not damage during the shipping process

Sustainability Check

⦁ We check on behalf of our customer if their vendors a

re sustainable in their practices or not.

⦁ Our customers are more confident to claim their product sustainable after our

100% Inspection

⦁ We visit factory and update our customer about production of a specific purchase order

⦁ Factory’s in-house data related to production process is checked and reported

WHY CHOOSE TEXTILIANS

Reliable, Affordable and Focused to Textile Industry in Pakistan

Textilians is more than a third party inspection company. We are deep rooted textile experts who born and serve in textile industry of Pakistan only. This gives us a unique benefit over the players operating in Pakistan from other countries. Since 2015 Textilians is providing Quality Control and Quality Assurance Inspection services.

Dedicated Team of Permanent Employed Inspectors

Expertise in all type of Textile Products

Standard Quality Control Services

Customized Quality Assurance Solutions

Following all International Quality Standards

Coverage to all over Pakistan

24/7 availability to conduct inspection

Competitive Prices

Excellent Single Point Response

Comprehensive Reporting Mechanism

Integrity

Transparency

Timely Response

Customer Satisfaction

Our Target Audience

We understand your needs based on the complex supply chain procedures and time lines sensitivity. We are also aware about the importance of product quality when it comes to online sales and e-tailing.

Retailers

We know mostly your products are already manufactured and not make to order. Our quality control solution and flexible approach make you confident about the quality of your merchandise.

Importers

We are well aware about the sensitivity of product quality in medical, hospitality and uniform industry. Parallel with you, we control and assure the quality along with conformity of the product functions.

Rental Companies

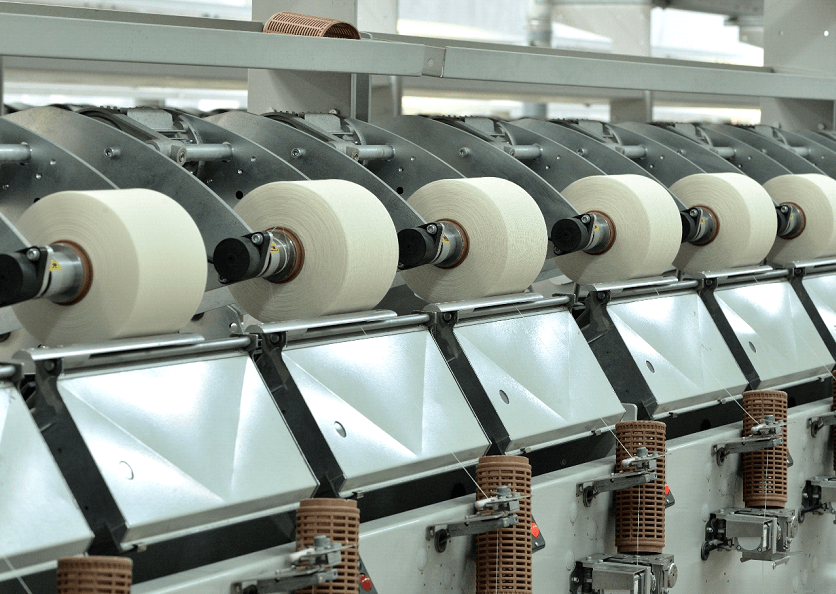

Pakistan is one of the largest exporters of yarn, greige fabric and finished fabric in the region. If you are a textile manufacturer and importing any type of textile raw material from Pakistan, then you are at the right place for yarn or fabric inspections.

Textile Manufacturers

Total Quality Management Solution

This segment of our quality services in very important for the clients who import textiles from any specific supplier on regular basis.

Textilians team design this specific solution to improve the product quality at a specific supplier gradually.

Products

Products We Inspect Most

Expertise in Textiles is our specialty. Without any doubt, we cover all kind of textile products being manufactured in Pakistan.

Ready to Wear

⦁ Tops & Bottoms

⦁ T Shirts, Polo Shirts, Sweat Shirts, Hoodies, Casual Shirts, Formal Shirts, Jackets etc

Sportswear

⦁ T Shirts, Polos, Bra, Vest, leggings, trousers, shorts, track suits,

Work wear

⦁ Tops & Bottoms

⦁ T Shirts, Polo Shirts, Sweat Shirts, Hoodies, Shirts, Jackets, Uppers, High Viz Vests

Children Wear

⦁ Tops, Bottoms & Rompers etc

⦁ T Shirts, Polo Shirts, Sweat Shirts, Hoodies,

Home Textiles

⦁ Bed Wear, Kitchen Wear, Home

Furnishing, Institutional Textil

Towels & Socks

⦁ Sports socks, Casual Socks, Formal Socks, Kids Socks, Leggings etc

Bags & Accessories

⦁ Promotional Textiles

Yarns

⦁ Ecru Yarns, Mercerized Yarns, Bleached Yarns, Dyed Yarns

Fabrics

⦁ Greige Fabrics, Dyed Fabrics, Finished Fabrics, Denim Fabrics, Printed Fabrics, PFGD Fabrics

Flexible:

Open to conduct Pre-Shipment Quality Inspections after office hours and during the week ends as well.

Responsible:

We choose cooperation over coordination and are proactive in our approach

Reliable:

Your eyes, ears and hands on the factory floor to save your time, money and avoid any risks

Stable:

Since 2015 Textilians is growing in its business of providing third party quality inspection services

HOW WE WORK

System should work and people should monitor

If you are importing any kind of textile product from Pakistan, we welcome you to avail our quality inspection services. In start we undergo a brief session of discussion with you to understand all detail about scope of your product, its specs and key areas of product quality you want to focus. Accordingly, we offer the best suitable solution for you out of our Quality Inspection services bucket.

Price is also locked at this stage and then we need all the technical details and quality manual from your side. Usually, we need a 24 hours’ notice to conduct inspection in the factory.

We are flexible in using our own reporting format or yours as well. After inspection a quick on-site report is get signed by the factory official and also shared with you right at the time. Detailed report with all pictorial evidences is shared on the next working day.

We use all possible ways of modern communication such as email, WhatsApp, Zoom, Microsoft Teams and Google Meet. We are quite available for any queries even after the inspection.

Coverage

All major textile production cities in Pakistan are covered by Textilians with local inspectors team available 24/7. This gives us a unique advantage to entertain our customers over a single call.

FAQ

Most Favorite Question

Phasellus ultricies ex vitae neque placerat porta. Aenean libero eros nec ultrices vel tristique non, porta eget dolor. Donec vel ipsum imperdiet sed neque, sit amet porta facilisis elit. Nunc neque enim finibus.

Nulla in nibh at leo faucibus molestie eget nec velit. Phasellus vel felis velit orci iaculis tempor tristique sagittis urna. Phasellus ac ante in lacus tempor egestas. Mauris molestie elit placerat, laoreet ex non posuere.

Nulla in nibh at leo faucibus molestie eget nec velit. Phasellus vel felis vel orci iaculis tempor tristique sagittis urna. Phasellus ac ante in lacus tempor egestas. Mauris molestie elit placerat, laoreet ex non posuere.

Nulla in nibh at leo faucibus molestie eget nec velit. Phasellus vel felis vel orci iaculis tempor tristique sagittis urna. Phasellus ac ante in lacus tempor egestas. Mauris molestie elit placerat, laoreet ex non posuere.

Nulla in nibh at leo faucibus molestie eget nec velit. Phasellus vel felis vel orci iaculis tempor tristique sagittis urna. Phasellus ac ante in lacus tempor egestas. Mauris molestie elit placerat, laoreet ex non posuere.

Nulla in nibh at leo faucibus molestie eget nec velit. Phasellus vel felis vel orci iaculis tempor tristique sagittis urna. Phasellus ac ante in lacus tempor egestas. Mauris molestie elit placerat, laoreet ex non posuere.

Nulla in nibh at leo faucibus molestie eget nec velit. Phasellus vel felis velit orci iaculis tempor tristique sagittis urna. Phasellus ac ante in lacus tempor egestas. Mauris molestie elit placerat, laoreet ex non posuere.

BLOG

Blog & Articles

In addition, we welcome textile traders, distributors and rental companies to avail our quality control and quality assurance services in order to enjoy smooth supply chain process in Pakistan.

Pakistan is huge when it comes to textile raw material export such as yarn, greige fabric and finished fabric. If you are a textile manufacturer and importing any type of textile raw material from Pakistan, then you are at the right place for your product conformity. Our team has hands on experience in yarn inspection and fabric inspection.

We understand the importance of brand image and high expectations of your clients. We are here in Pakistan to partner you in post covid challenges to your business.

Brands